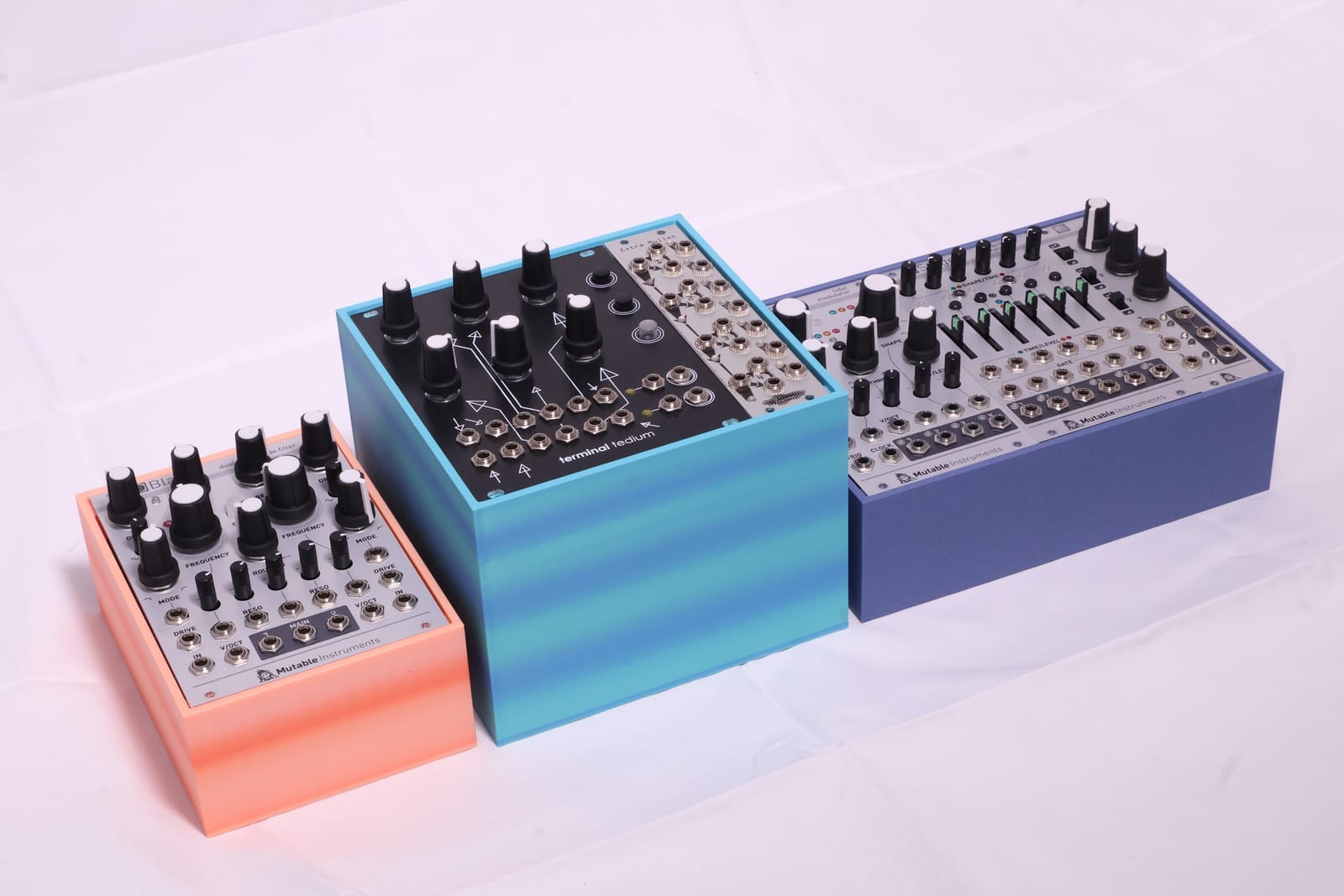

Since its introduction in 1995, EuroRack - a specialised format for modular synthesizers - has grown to become almost ubiquitous in the music hardware world.

If you're new to this arena, Eurorack is a standard for mounting, powering and connecting synthesisers, effects and other modules to create new and interesting sounds from hardware. Think of it as a Lego set for creating synthesisers from individual building blocks, or modules.

The specification for EuroRack is simple, including:

- Standards for modules: Every Eurorack module has the same height (5.06") and width multiples (measured in HP - Horizontal Pitch). This lets you mix and match modules from different manufacturers without worrying about compatibility.

- Standards for electronics: As well as the physical dimensions of the mounting system for modules, there are also set standards for power, audio signal and control voltages. This ensures any modules that fit will play nicely with one another.

- Cable-based patching: Modules interface with one another via patch cables, sending signals between them to shape and manipulate sound. This allows for endless experimentation and sound design possibilities.

- Wide variety of modules: Ranging from low-production-volume boutique products to high-performance modules from household names like Moog, current estimates place the number of available, compatible modules at 15,000.

For this post, that's about all of the background needed, but the rabbit hole goes much deeper for those with an interest.

Introducing Tiny Rack: A New Solution for DIY Synths

GitHub user and music hardware hacker KevinKeWang's Tiny Rack project is designed to further lower the barrier to entry for those starting out with DIY modular synthesis. It takes the great standards and module availability of the EuroRack format and makes it easy for those with some technical know-how (and access to a 3D printer) to spin up their own mounting and power system for their devices.

Previously, modular synths would require you to either custom-build a rack out of wood or metal, or buy an expensive off-shelf solution, or some hybrid of the two with custom modifications to existing products. Power delivery, too, has always been a challenge for new users; there are a huge number of options, and they don't all work with all modules. Switching power supplies, for example, often fail to work with some types of synth module.

Tiny Rack seeks to address both of these challenges, which is great for producers with a growing collection, those who have a loved synth configuration in need of a dedicated home, and DIYers who are actively prototyping new modules of their own from scratch. It also presents a great opportunity to learn more about how your modules work - or how they're powered, at least.

Per GitHub, KevinKeWang's reasoning behind creating the project is simple:

The main reason I started this project was the difficulty in finding a simple power bank solution when I was just starting out with DIY modules. Most of the solutions required specialized rails. [I] needed to control the precision otherwise the modules would be difficult to install. there were many power board solutions but I couldn't be sure about the quality of their output. Some switching power supplies cause digital modulars to fail to boot.

And if you aren't able to print the project at home, or if you're not comfortable soldering a custom power board that's going to be delivering voltage to your pride and joy, don't worry. You can also buy Tiny Rack modules and boards direct from Kevin's company Biti Workshop via Reverb.com. They run around £100 for the power boards and £200 for the full racks.

What's Included in the Project Files?

The project's repo keeps things simple - there are a variety of STL and G-code files available ready to be 3D printed (or ordered from an online service), and some beautiful board schematics and CAD files ready to be fabricated to deliver 12V power to your modules.

A nice addition is the optional inclusion of +3.3v power for use with microcontrollers and music hardware that operate at lower voltages than traditional synth modules, such as the Arduino and ESP32. This is awesome news for hardware hackers and those looking for an all-in-one solution for prototyping that reduces the need to add a mess of power leads, crocodile clips and Dupont connectors to their patch cables.

Better still is the option to run the whole setup from a power bank, enabling you to make your hardware at least semi-portable. This isn't dwelled on for long in the readme (though there are some great example photos), but for some users this will no doubt be a game changer.

The project is released under a CC-BY-SA license, which means you can do pretty much whatever you want with the files to make it your own. You can even sell products you make based on this project if you come up with something great. The only restriction is that you equally share anything you make under the same conditions. We love open source and this is a great choice by the proprietor.

Head over to GitHub now for more gorgeous images and a great summary of the project and how to get started - but be prepared for some long print times. The main rack model will use almost a kilogram of filament (or, the best part of a full spool) and take about a full day to print on a Bambu Labs P1S. Your mileage may vary with other printers, but we'd recommend following the instructions closely and doing some smaller test prints first.

Also, be sure to read out more from the sources that brought this project to our attention: